Tensile Force Controller

The most innovative tensile force controller in winding technology: The electromagnetic dancer

The electromagnetic dancer is the innovation in the automatic regulation of tensile force or tensile stress of delicate wound goods, for example to withdraw, spool, rewind or wind wire, delicate wire, flat wire of various types and with various alloys, fibres, chemical fibres, glass fibres, textile fibres, stranded wire, fine tubes, tape, film, fibre optic cables, solder and much more.

|

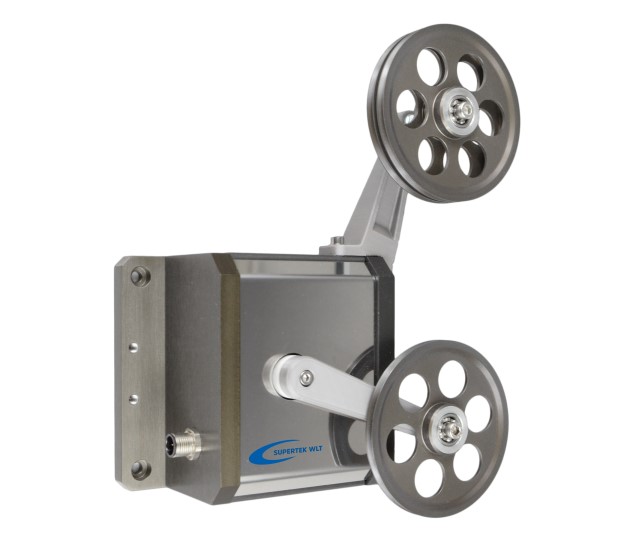

| Electromagnetic dancer EDL-60 |

| For all traction applications from 10cN to 600cN. Dancer force bandwidth: 20cN-1200cN Especially suitable for fine wires, optical fibers, fibers, etc.

|

|

Instead of the traditional dancer controller that applies the dancer force using weights, springs or in combination with pneumatic cylinders, the dancer force of the electromagnetic dancer always remains constant regardless of the dancer position thanks to the patented electromagnetic force method. A deviation from the central position of the dancer arm thus does not lead to any change in tensile force or tensile stress. The deviation of the dancer position only adjusts the dancer position for the drive motor. Compared with other tensile force controllers, this technical advantage offers a significantly easier and at the same time more optimum drive adjustment with efficient compensation of disturbances without changing the tensile stress or the winding tension. |

|

Advantages over traditional systems:

|

|

| Adjustment of tension |

|

|

How is the dancer used?

|

|

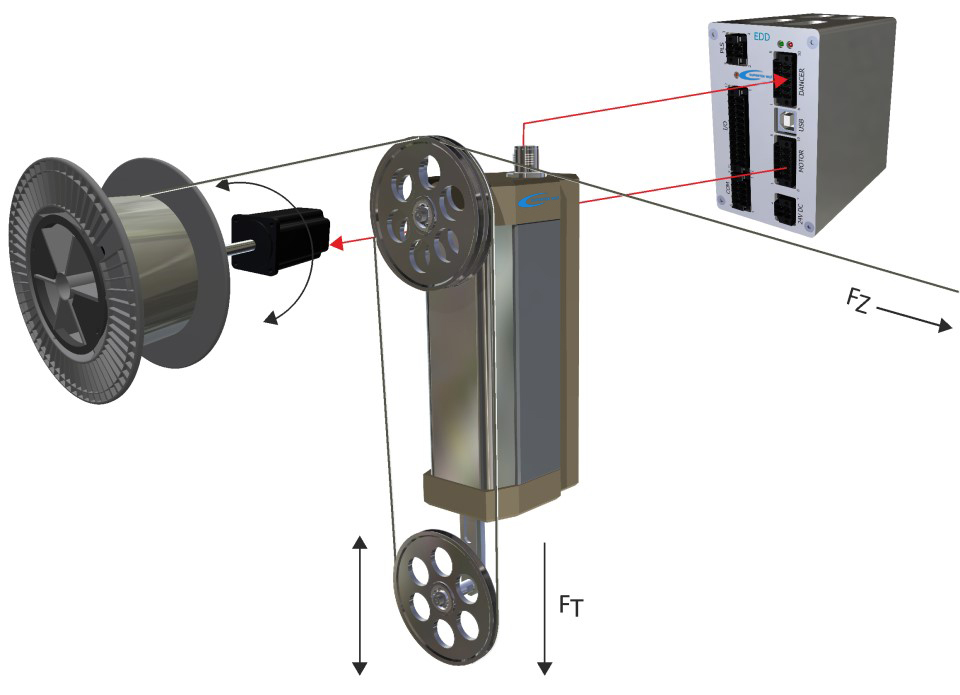

The tensile force (FZ) is proportional to the dancer force (FT). The dancer force always remains constant regardless of the dancer position.

A deviation from the central position of the dancer arm thus does not lead to any change in tensile force. The deviation only readjusts the drive motor.

This technical advantage offers a simple and at the same time optimum drive control with efficient compensation of disturbances without changing the winding tension. |

The dancer force can easily be adjusted by analogue means or using a BUS system.

For the best possible processing of your materials the dancer force of the electromagnetic dancer and thus the line tensile strength can be adjusted sensitively, depending on the model, to a thousandth of a Newton (mN) or a hundredth of a gram.

Unlike traditional tensile force adjustment systems, such as pneumatic or mechanical dancers, wire tension controllers, wire tensioners, tensile stress meters etc., the electromagnetic force creation principle patented by Supertek is used for the dancer.

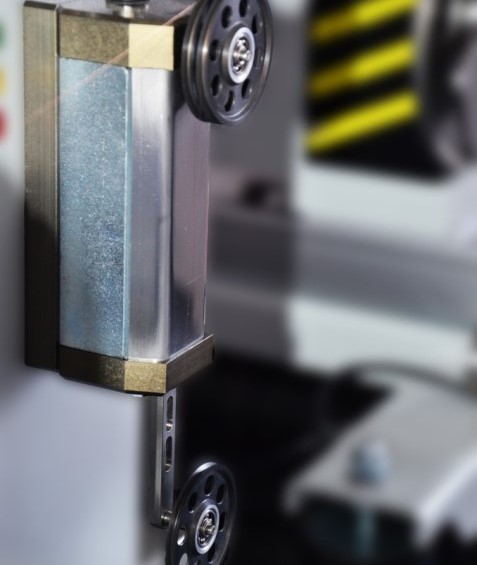

The patented electromagnetic dancer creates a homogeneous dancer force over the whole dancer stroke and enables highly accurate tensile force control and measurement in one unit.

The tensile force or tensile stress is measured by the implicit electromagnetic scales principle (magnetic susceptibility).

The dimensions of the dancer arm and the guide roller are compensated for by the automatic calibration system so that different return pulleys or feed rollers can be used.

The dancer force of the electromagnetic dancer is not susceptible to interference in relation to the dancer movement and thus allows a motor control deviation and other interference, such as changes in line speed without changing the specified tensile stress as a result. Thus the electromagnetic dancer is also suitable for very dynamic and intermittent processes.

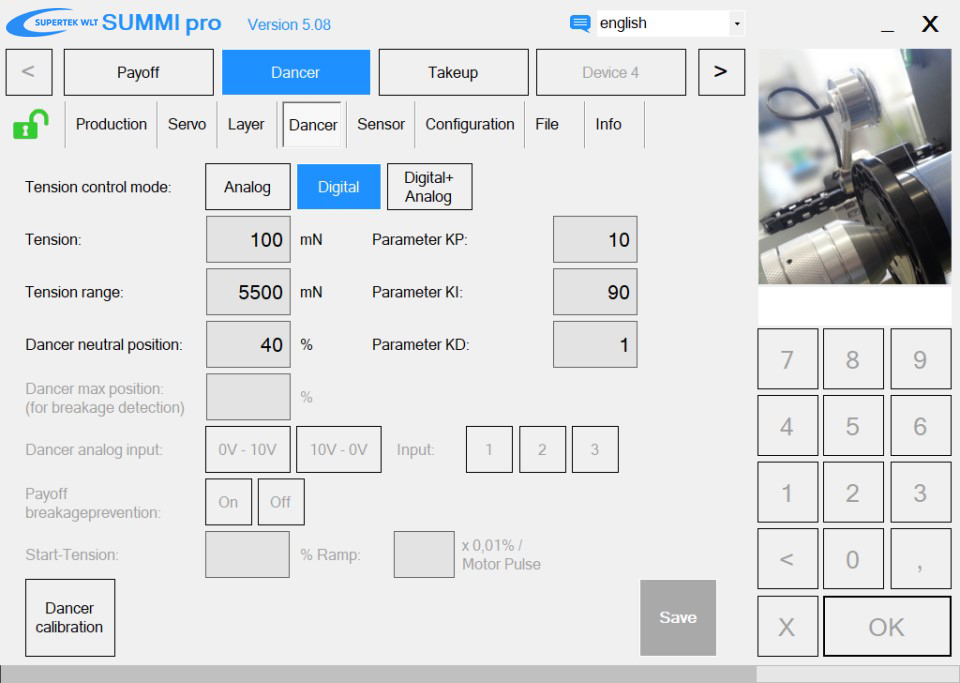

An automatic dancer position controller or dancer controller that is already integrated into the electromagnetic dancer as a PID controller is used for the active tensile force control of the electromagnetic dancer in combination with a speed-adjustable motor, capstan or winder.

The reference variable of the dancer controller is the dancer position that is recorded contactlessly by the electromagnetic dancer (0-10V) and provided for the internal controller or the controller provided by the customer. Other signal outputs are available for the up, down dancer positions, crack detection etc.

The reference variable of the dancer controller is normally the central dancer position (5V) and can also be set individually for the internal PID controller.

Depending on the speed adjustable motor used, e.g. asynchronous motor, synchronous motor, servo motor, step motor, etc., the correcting variable of the integrated dancer controller can be adjusted to the frequency converter, servo amplifier or step motor driver. For this there is a selection of analogue, digital or pulse-controlled correcting variables available for the electromagnetic dancer.

Depending on the version of the electromagnetic dancer or integrated dancer controller, the dancer force can be adjusted and the integrated PID dancer controller can be configured with the normal standardised data transfers.

A convenient solution for adjusting the dancer force, tensile force or tensile stress and the dancer controller parameters is to use Supertek's operating devices, such as the CMC or touch panel. Obviously the dancer force, tensile force or tensile stress can also be adjusted by analogue methods, particularly for older winding machines or via digital communication via other manufacturer's existing or planned PLC systems, for example Siemens, Beckhoff, Allen-Bradley etc. The tensile force can be changed if necessary while the current process is running. Local access to the dancer's parameters and by storing the process data, such as the dancer force, tensile force or tensile stress of the electromagnetic dancer externally, meets Industry 4.0 ideas and enables consistent traceability (track and traceability) during the coiling and winding processes.

The high tensile force range of the electromagnetic dancer enables the tensile force of the various materials to be adjusted easily and flexibly without having to retool the machine. The exact reproducibility of the tensile force makes consistent quality possible even after several product changes.

Due to the small, compact footprint and ease of assembly, the electromagnetic dancer is very easy to integrate for many applications, existing or new machines.

A rapid payback period is achieved compared with other solutions due to the low unit and assembly costs and the significant increase in quality.

Examples of use:

- Unwinder, uncoiler, dispensers

- Shaft winder, shaft unwinder

- Reel, drum winder

- Capstan

- Dancer systems with product buffer

- Winder, take-up, roller

- Winding machine, stranding machine

- Rewinding system, rewinding machine, extruder, mill, drawing die, extrusion die, fibre glass draw tower

- Annealing furnace, dyeing plant

| Customer's quote |

| I can delicately adjust the dancer force of the electromagnetic dancer and thus the line tensile force precisely to a thousandth of a Newton (mN) or a hundredth of a gram in order to process my fibre optic cables in a dyeing plant. Previously we had a mechanical spring dancer which resulted in great fluctuations in quality up to rejects in the damping test. Since the electromagnetic dancer has been installed I can adjust the tensile force precisely and obtain constantly high quality for my fibre optic cables. We haven't had any rejects for five years. |